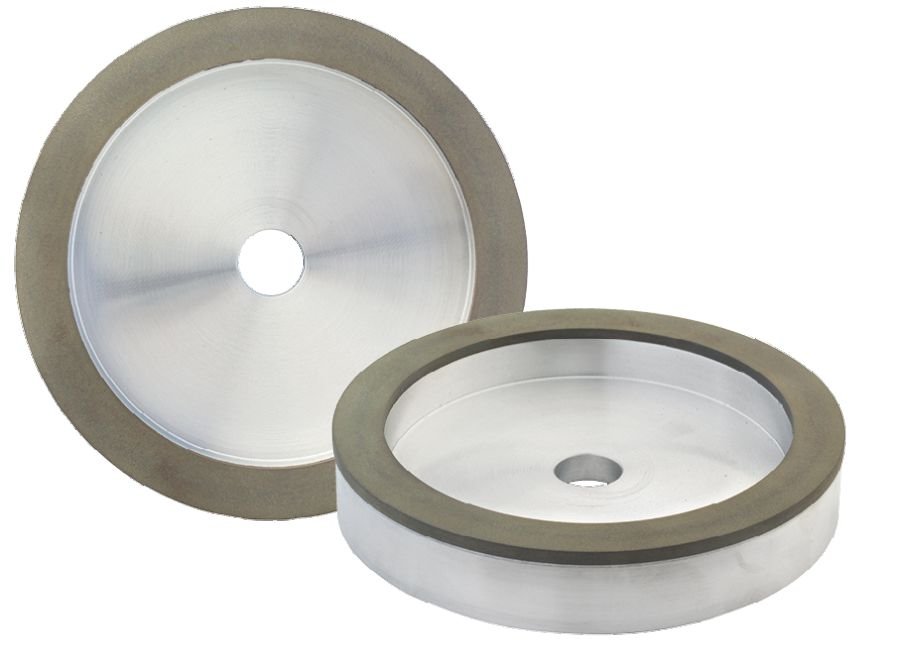

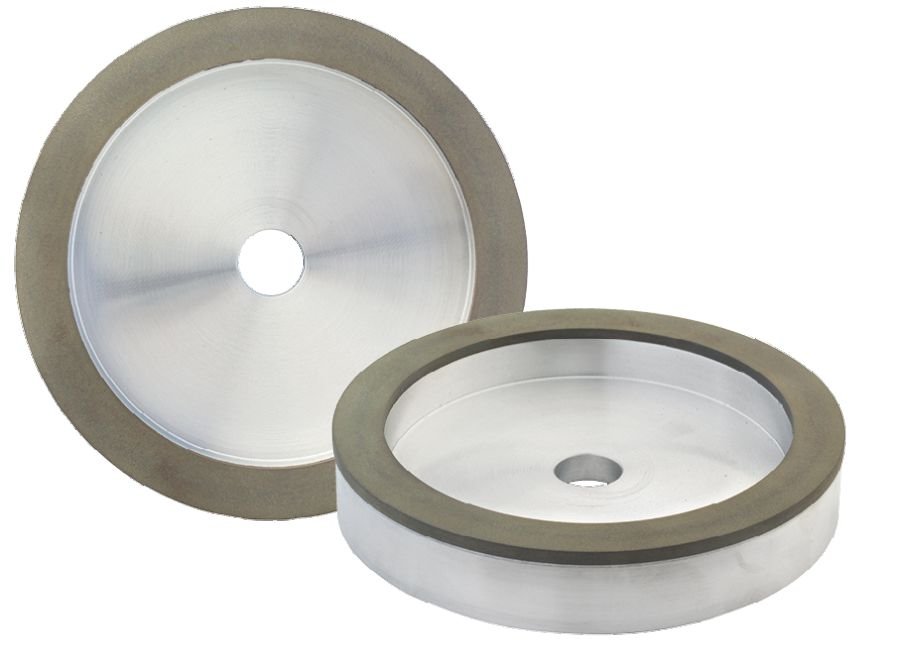

Resin Bond Grinding Wheels – Versatile & High-Precision Performance

Achieve Superior Grinding & Polishing with Resin Bond Wheels

About Resin Bond

Why Choose Resin Bond Grinding Wheels?

Resin bond grinding wheels are widely recognized for their versatility, high cutting efficiency, and smooth grinding action. Their unique composition blends diamond or CBN grains with advanced resin formulations, creating a bond that is both strong and flexible.

One of the standout advantages of resin bond wheels is their self-sharpening ability, which maintains peak grinding performance while minimizing wheel dressing requirements. Additionally, they generate less heat, reducing the risk of thermal damage or burns on the workpiece, making them an excellent choice for precision applications requiring a fine surface finish.

Resin bond wheels also offer superior vibration dampening, resulting in stable grinding performance with minimal chatter. Their ability to be used in both wet and dry conditions adds to their versatility, making them a preferred solution across industries like automotive, aerospace, tooling, and ceramics.

With high feed rates, improved surface roughness, and long-lasting performance, Mahlen Abrasive’s resin bond grinding wheels are the go-to solution for professionals seeking efficiency and precision.

Key Features & Benefits

Free-Cutting Performance

Superior Heat Resistance

Self-Sharpening Properties

High Grinding Efficiency

Versatile Application

Extended Wheel Life

Applications – Where Resin Bond Wheels Excel

About Our Company

TURNING VISION INTO REALITY

Founded in 1992 and based in Bhavnagar, Gujarat, India, our company has grown into a trusted name in the super abrasives industry. Through advanced technology, meticulous craftsmanship, and a customer-centric approach, we have established a reputation for quality, reliability, and excellence.

Partner with us and experience the difference in quality, service, and expertise that sets us apart in the global market.

FAQs

Everything You Need to Know