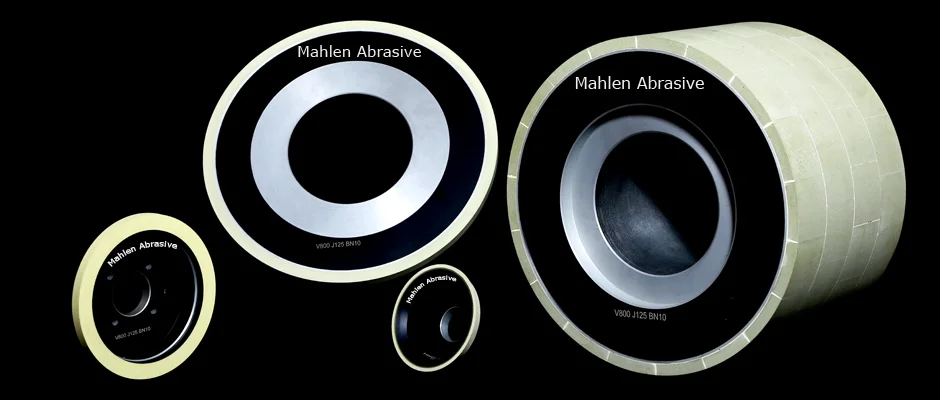

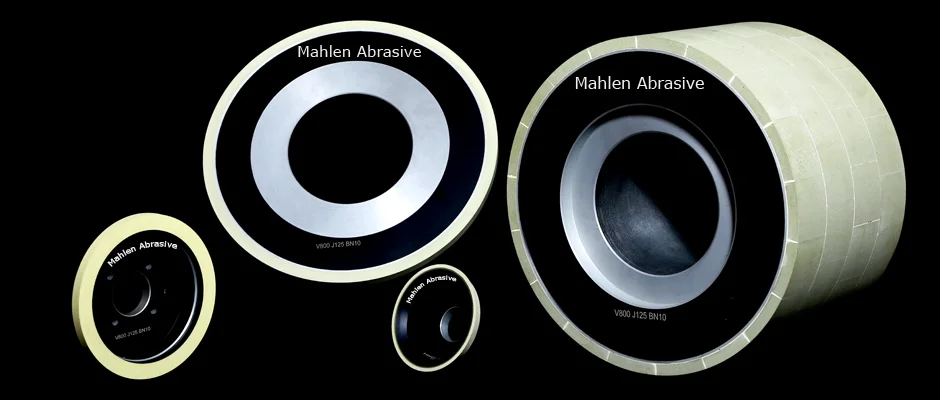

Vitrified Diamond Grinding Wheel

Vitrified Diamond Grinding Wheel

About Vitrified Grinding Wheels

Why Choose Vitrified Grinding Wheels?

Vitrified grinding wheels are the industry standard for achieving precision, efficiency, and reliability in the machining of advanced materials. These wheels are particularly favored for the grinding of PCD (polycrystalline diamond) and PCBN (polycrystalline cubic boron nitride) tools due to their exceptional performance and ability to deliver superior surface finishes with minimal effort.

Engineered for durability and consistent results, vitrified grinding wheels from Mahlen Abrasive provide outstanding productivity while reducing downtime and enhancing tool longevity. They are also suitable for fabricating natural diamond and dense ceramic materials, making them versatile for a wide range of applications.

When you choose Mahlen Abrasive vitrified grinding wheels, you’re selecting a product backed by years of expertise, cutting-edge technology, and superior raw materials. If you need guidance in identifying the perfect grinding wheel for your application, our team of experts is ready to assist.

Features and Benefits

Precision Performance

Superior Durability

Versatile Applications

Enhanced Efficiency

Exceptional Surface Finish

Custom Solutions

Applications of Vitrified Grinding Wheels

Paper Manufacturing: OD grinding of printing rolls to maintain consistent and smooth performance.

PCD and PCBN Tools: Surface grinding, profiling, and sharpening of cutting tools made of polycrystalline materials.

Threading Plates: Profile grinding of tungsten carbide (TC) threading plates for long-lasting performance.

Ceramic Components: Flat grinding of dense ceramic parts for industrial and engineering applications.

About Our Company

TURNING VISION INTO REALITY

Founded in 1992 and based in Bhavnagar, Gujarat, India, our company has grown into a trusted name in the super abrasives industry. Through advanced technology, meticulous craftsmanship, and a customer-centric approach, we have established a reputation for quality, reliability, and excellence.

Partner with us and experience the difference in quality, service, and expertise that sets us apart in the global market.

FAQs

Everything You Need to Know